Aluminum Sheet

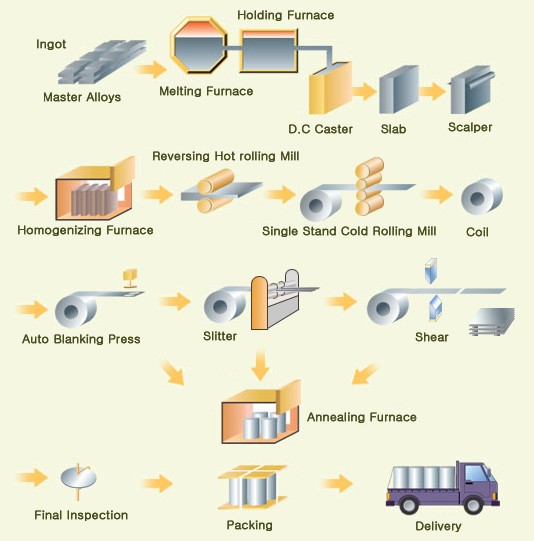

Process Flow

![]() > ALSheet > Process Flow

> ALSheet > Process Flow

Process overview

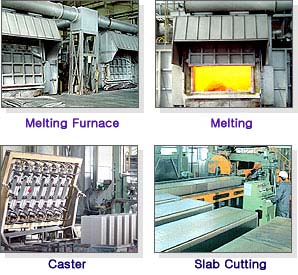

1. Melting & Casting

his process is designed to cast the slab with D.C casting method by removing impurities and performing degassing and solidifying treatments after putting ingot into the melting furnace. The production of multiple items in small q'ty is available due to use of variable mold. This Process is equipped with many kinds of the state of the art equipments enough to produce top quality aluminum alloys.

Main equipments

Melting Furnace : 23ton * 2units

Holding Furnace : 20ton * 1unit

Continuous Melting Device

Caster : 20ton/CH

2. Hot Mill

This process is intended to produce hot rolled coil with a thickness suitable for cold rolling process by applying hot rolling after scalping and soaking the cast slab. High quality hot rolled coil is available by the latest rolling mill that can also carry out quality analysis.

Main equipments

Slab Scalper : 1unit

Hot Rolling Mill : 1unit

Slab Homogenzing : 40ton * 4units

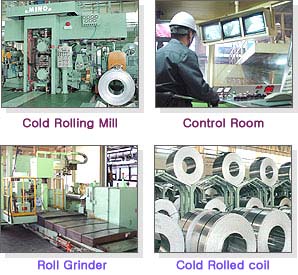

3. Cold Mill

This process is designed to control such requirements that products should meet as strength, thckness, elongation and other mechanical properies by performing cold rolling. Mostly the products with 0.3T~4.8T are available.

Main equipments

Cold Rolling Mill : 2units

Roll Grinder

Available Dimensions

- Thickness : 0.5 ~ 4.6mm

- Width : 500 ~ 750mm

- Outside Diameter : Max. 1,300mm

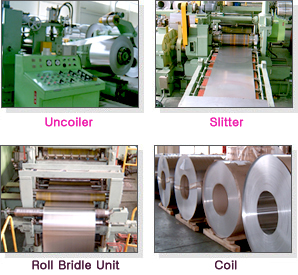

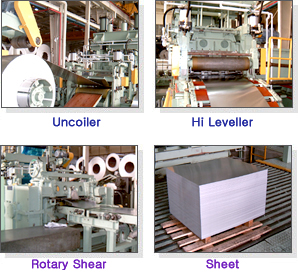

4. Finishing

This is final process producing kinds of circle, coil, sheets through shearing, slitting and annealing the cold rolled coil. We possess automatic blanking press, slitting machine combined with washer and micro-flat functioned mini shearing machine which can supply various kinds & small q'ty quality sheet with early delivery.

Main equipments

Automatic Continuous

Blanking Press : 5units

Annealing Furnace : 15ton * 3units, 4ton * 1unit

5. Slitter Line

| Process | Slitter Line |

| Coil Weight | 3 ton |

| Thcikness | 0.3 - 4.7 mm |

| Tolerance | + - 0.05 mm |

| Output | 1,000 ton |

6. Shear Line

| Process | Shear Line |

| Coil Weight | 3 ton |

| Thcikness | 0.3 - 4.7 mm |

| Tolerance | + - 0.01 mm |

| Output | 600 ton |