Aluminum Sheet

Facilities

![]() > ALSheet > Facilities

> ALSheet > Facilities

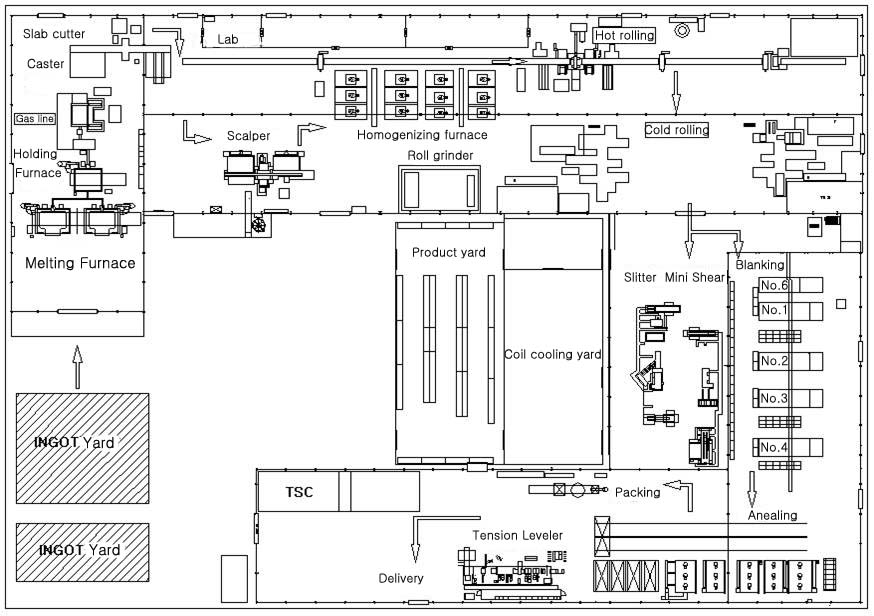

Layout of facilities

FACILITIES

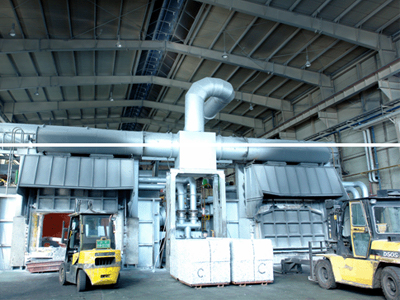

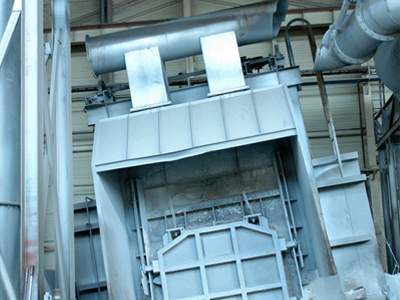

23 ton Furnace 2 set

faility to melt aluminum ingot, scrap generated in factory and master alloy

20 ton Holding Furnace 1 set

faility to maintain the ingredient for alloy before the casting and hold the casting temperature the alloy ingredient and casting temperature

caster

Facility to produce slab in desired standards using direct chill method

Pusher Furnace

Facility to promote uniformity of casting structure through heat processing of trimmed slab overre-crystallization temperature and preheat trimmed slab in Hot Mill. with adequate temperature.

Hot Mill.

Facility to process milling to thickness proper for cold mill. over the re-crystallization temperature.

Cold Mill.

Facility to carry out plastic working of coil underwent HOT Mill. to thickness and physical properties demanded by the customers.

Slitter

Facility to cut the coil underwent Cold Mill. in longitudinal direction of which meets the width standards of rectangular sheet (width X length) demanded by the customers.

Mini Shear

Facility to cut the coil cut to meet the standards of rectangular sheet (width X length) in horizontal direction that meets the standards for length

Circling Machine

Facility equipped with auto feeding system to meet the standards of circle sheet demanded by the customers

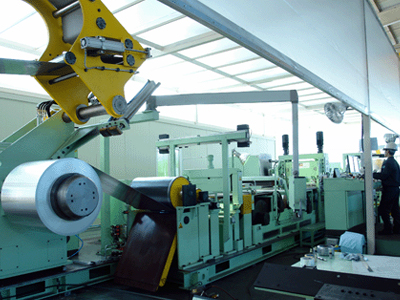

Tension Leveller

Facility to reform the coil underwent cold mill, to acquire the form that meets the flatness of sheet demanded by the customers

Annealing Furnace

Heat-processing facility to secure the physical properties demanded by the customers by resolving the strain hardening generated during cold mill.